Typically the Engineering and Manufacturing Industries operate in :

» Make to stock

» Assemble to order

» Job shop

» Make to order

» Engineer to order

» Project based environment.

This very nature of order management decides the

optimisation strategies of planning, procurement, inventory management patterns. The ERP application must address

mechanism to handle such item management strategies.

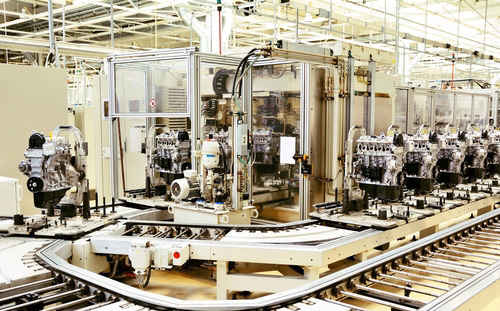

DISCRETE MANUFACTURING

Challenges for Discrete Manufacturing

SAP Business One is a breakthrough in business management software built from the ground up for small and mid sized businesses. SAP Business One is a single piece of software that puts business users in charge – so you gain increased control and achieve greater insight into your business. Automate and integrate all the critical functions of your organization including Manufacturing, Inventory, Finance and accounting, Management, purchasing, Banking and Customer Relationship Management. Solution components for the seamless integration to Quality Assurance / Quality Checking, Research & Development, Master Production Scheduling and compliance reporting functionalities are available.

Order Management

Customer Specific Product Design for a Single Item

Multiple bill of material for single item has been a common requirement in this industry as the customer defines the design he requires. According to customer requirement, there is no need to alter the bill of material and process plan. This hinders the process planned and hence cause delays in delivery.

Sub Contracting Management

Most of the engineering companies manage sub- contracting to meet the demand. Generation of challans and maintaining the stock status of material lying at the subcontract location is very important.

Production Planning

Electronics industry incurs high costs in inventory due to lack of visibility of the stock in work-in-progress stage. An insight on the inventory in WIP stage can help the companies plan their production more efficiently towards meeting the delivery schedules. The production planning should address the planning of the production lines by considering the availability of lines and throughput times as well as order dispatch dates.

Multiple Site Management

Engineering companies find it difficult to manage and control several projects simultaneously at multiple locations. The key processes like project estimation, bills of material creation, quote submissions and project profitability report for different projects at multiple locations add to it.